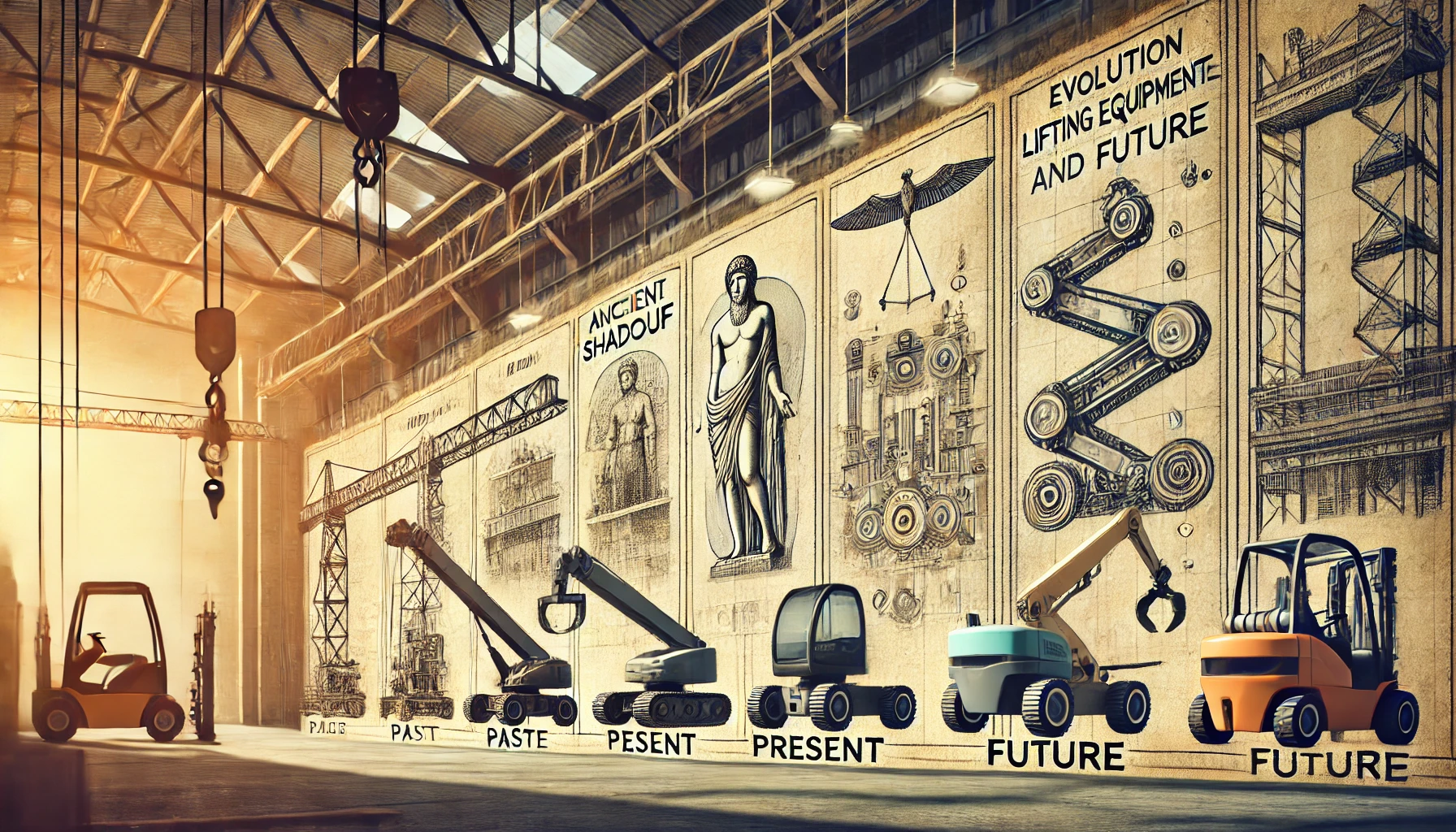

Lifting machines have changed over the centuries, one of the major changes has been incorporation of aiding technology and this shift has enabled humanity to safely and efficiently lift hefty loads. Lifting devices have seen a journey along with humanity’s advancement, beginning from complex machines of ancient times and leading to advanced systems today. These devices played a critical role in elevating construction and manufacturing among other industries.

Ancient Times

The first ever lifting machine is believed to be the shadouf. Its origins can be linked back to Mesopotamia 3000 years before Christ. The device consisted of a lever and had a primary function of irrigation, assisting in elevating water from lower to higher land. By 2000 B.C shadouf was incorporated into ancient engineering practices, particularly in Egypt signifying its importance. Its mechanism proved to be a useful addition for many processes.

The Greeks relied on advanced building mechanisms, this is where cranes were developed. With the addition of cranes in ancient Greece around the 6th century B.C, heavy loads could easily be lifted, which is proven through the large cuttings present on lewis irons and lifting tongs used on Greek temples stone blocks. These devices made construction of significant infrastructure much easier, eliminating the need for exhausting methods such as ramps.

Industrial Revolution and Mechanization

The introduction of steam power during the Industrial Revolution of the 18th and 19th centuries enabled the development of steam cranes and steam hoists. These powerful machines were able to operate with greater precision while lifting heavier loads, therefore revolutionizing the construction and manufacturing processes. During this time, industrial lifting equipment grew tremendously due to the steam powered devices. The introduction of iron and steel primarily enabled strong and durable building structures which shaped the modern world.

Modern Advancements

Another major growth in lifting technology was between the 20th and 21st century with the development of forklift motors, mobile cranes, and electric overhead cranes. Electric and hydraulic systems provided the power needed for heavy duty tasks while making the lifting operation more controllable and smoother. During this time self-activated brakes, lift limiters, and other safety features were incorporated into the lifting devices to reduce the chances of mishaps.

Current Innovations

Today’s automated machinery has evolved dramatically, resulting in the incorporation of digital technologies aimed at ensuring safety and improved efficiency. With the integration of the Internet of Things comes the Smart lifting systems which have sensors for real-time monitoring of load weight, tension, and equipment health. Furthermore, these technologies allow for predictive maintenance which minimizes the chances of equipment failure.

The employment of automation and robotics has increased greatly allowing for more efficient lifting operations. With highly automated systems, monotonous tasks can be performed with high accuracy, reducing human errors and increasing productivity. For example, AGVs (automated guided vehicles) and robotic arms are now extensively used for material handling within warehouses and production plants.

Future Trends

The lifting equipment industry is predicted to witness new trends which are set to emerge in the near future.

- Application of Artificial Intelligence (AI): Development of AI algorithms which enhance lifting operations by providing analytical solutions that are applicable in real time situations are on the rise. This includes advanced systems that optimize routes for material handling as well as adaptive control systems that alter to different environments.

- Sustainability Initiatives: More and more attention is being paid to making lifting and handling equipment that is more environmentally friendly. Various manufacturers are looking at new, lightweight and strong materials like carbon fiber and nano-engineered composites, which will enhance the handling of the equipment as well as lighten the fuel consumption. Moreover, lifting and handling machinery with electric and hybrid power systems are being developed to lessen the greenhouse gas emissions and energy usage.

- Virtual and Augmented Reality (VR/AR): In the training field, VR and AR technologies are put to use for operators to gain experience in a simulated setting with little to no physical risk. This helps them deeply understand how the lifting process works, as well as how to act during safety-critical situations.

Conclusion

The development of lifting machinery from the simple shadouf to advanced and smart lifting systems is a clear demonstration of people’s never-ending need to solve problems of a physical nature. The world will continue to develop, along with the industry where people need to use the lifting equipment which will create greater productivity while drastically improving safety and environmentally-friendly measures within the construction, fabrication, and many other fields.